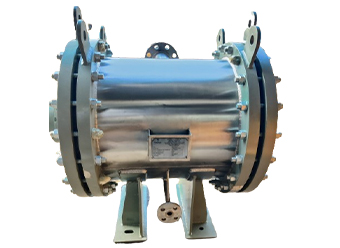

Spiral Type Heat Exchanger

The spiral plate heat exchanger is made by rolling two long metal plates around a center core to form two concentric spiral flow passages, one for each fluid. The plate edges are welded shut so that each fluid stays within its own passage and there is no flow bypassing or intermixing.

A Spiral Type Heat Exchanger consists of two flat metal plates wound around a central core, forming two separate spiral channels. One fluid flows through the inner channel while the other flows through the outer channel in a counterflow arrangement. This design maximizes the heat transfer area and ensures a high heat transfer coefficient.

Applications :

- Chemical Industry:Used for heating, cooling, and heat recovery processes, especially with viscous or fouling fluids.

- Petrochemical Industry: Ideal for processes involving heavy oils, slurries, and other challenging fluids.

- Wastewater Treatment: Efficient in treating and recovering heat from wastewater streams.

- Food and Beverage: Suitable for pasteurization, sterilization, and other thermal processes.

- Pharmaceutical Industry: Applied in processes requiring precise temperature control and cleanliness.