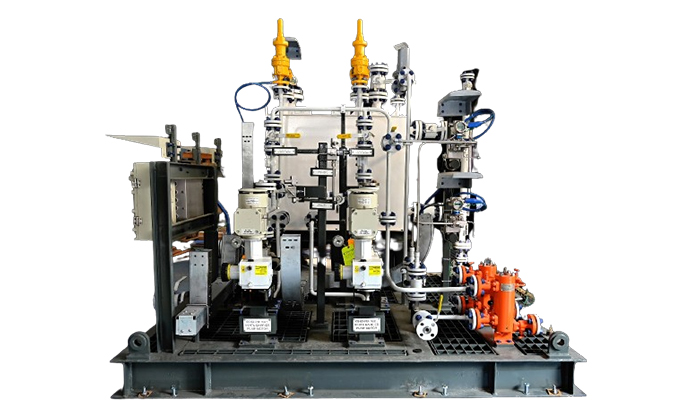

Mechanical Seal Support System

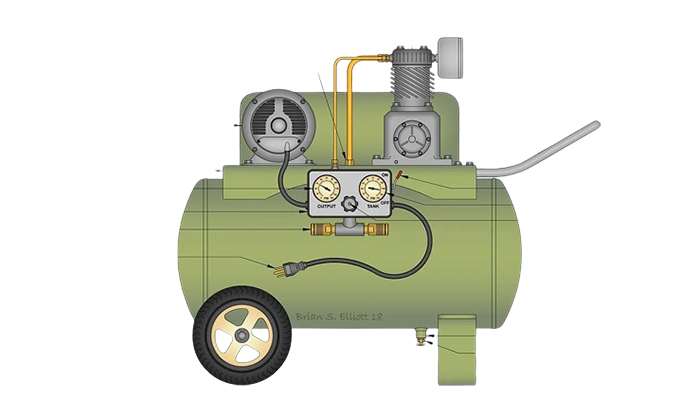

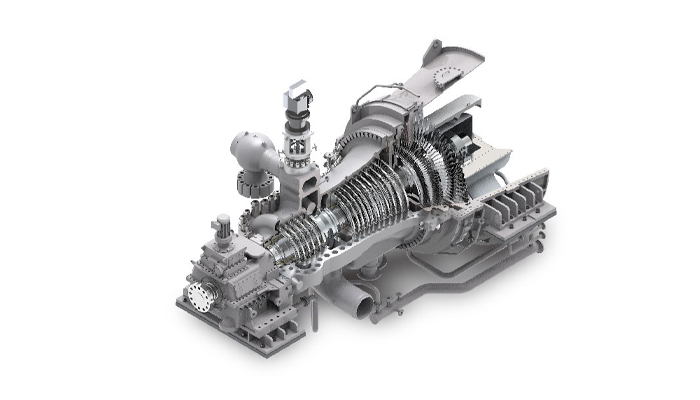

Seal support systems are used on a variety of rotating equipment, including pumps, compressors, mixers, steam turbines and other specialty equipment. They have application in the oil and gas, pharmaceutical, chemical processing, mineral and ore processing, and general industries.

A Mechanical Seal Support System is a critical component used in rotating equipment, such as pumps, compressors, and mixers, to prevent fluid leakage along the rotating shaft. These systems consist of several key elements, including a rotating seal ring (primary ring) and a stationary seal ring (mating ring), which work together to create a tight seal. The rotating ring is attached to the shaft, while the stationary ring is fixed to the housing. Secondary seals, such as O-rings or gaskets, provide additional sealing between these components and the equipment housing. A spring mechanism ensures that the seal faces remain in contact, while a drive mechanism prevents slippage.

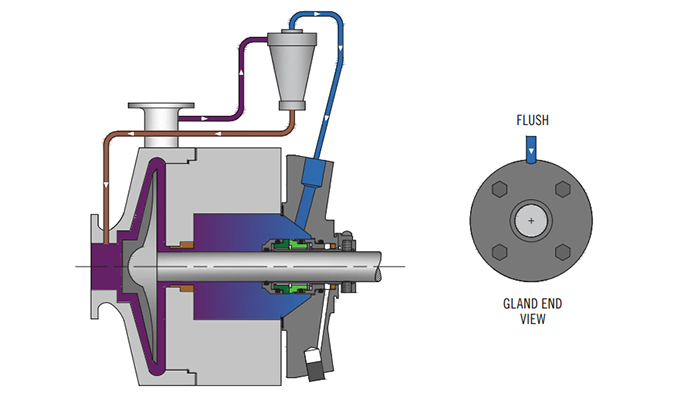

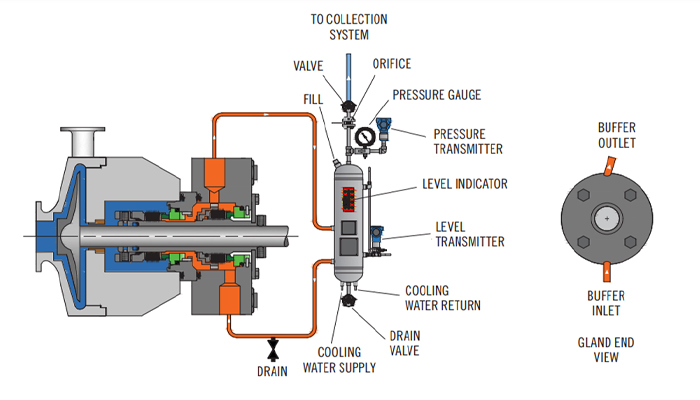

Seal housings or glands encase the entire assembly and often incorporate cooling or flushing systems to enhance performance and durability. Mechanical seals are designed to handle various pressures and temperatures, with materials selected based on fluid compatibility and operating conditions. They come in different types, including balanced and unbalanced seals, cartridge seals, pusher and non-pusher seals, each suited to specific applications. Proper installation and maintenance are essential for optimal performance, making mechanical seals a reliable and efficient solution for preventing leaks and ensuring the smooth operation of industrial equipment.